When a vehicle starts making unusual sounds, specifically a clicking noise under the hood, it might be a sign of a rocker arm issue.

Rocker arms are pivotal components in an engine’s valve train, translating the camshaft’s circular motion into the vertical motion needed to open and close the valves.

If these rocker arms are not functioning correctly, they can lead to a range of engine problems, from misfires to an illuminated check engine light.

Identifying the symptoms of a failing rocker arm is critical for timely maintenance. Owners may notice an increase in engine noise, predominantly clicking or ticking sounds, which are often the earliest indicators of wear or damage.

Performance issues, such as engine misfires and a noticeable loss of power, can also manifest, potentially leading to an illuminated check engine light.

Understanding Rocker Arm Repairs

Identifying Common Issues

The rocker arms in an engine play a crucial role in actuating valves for proper air and fuel flow through the combustion chamber.

Common issues with rocker arms include a persistent ticking noise, which often indicates excessive clearance or a failing lifter.

Other symptoms might be engine misfires, stalling, or a noticeable decrease in engine performance. If not addressed, issues with rocker arms can lead to warped valves, bent valves, or other significant engine damage.

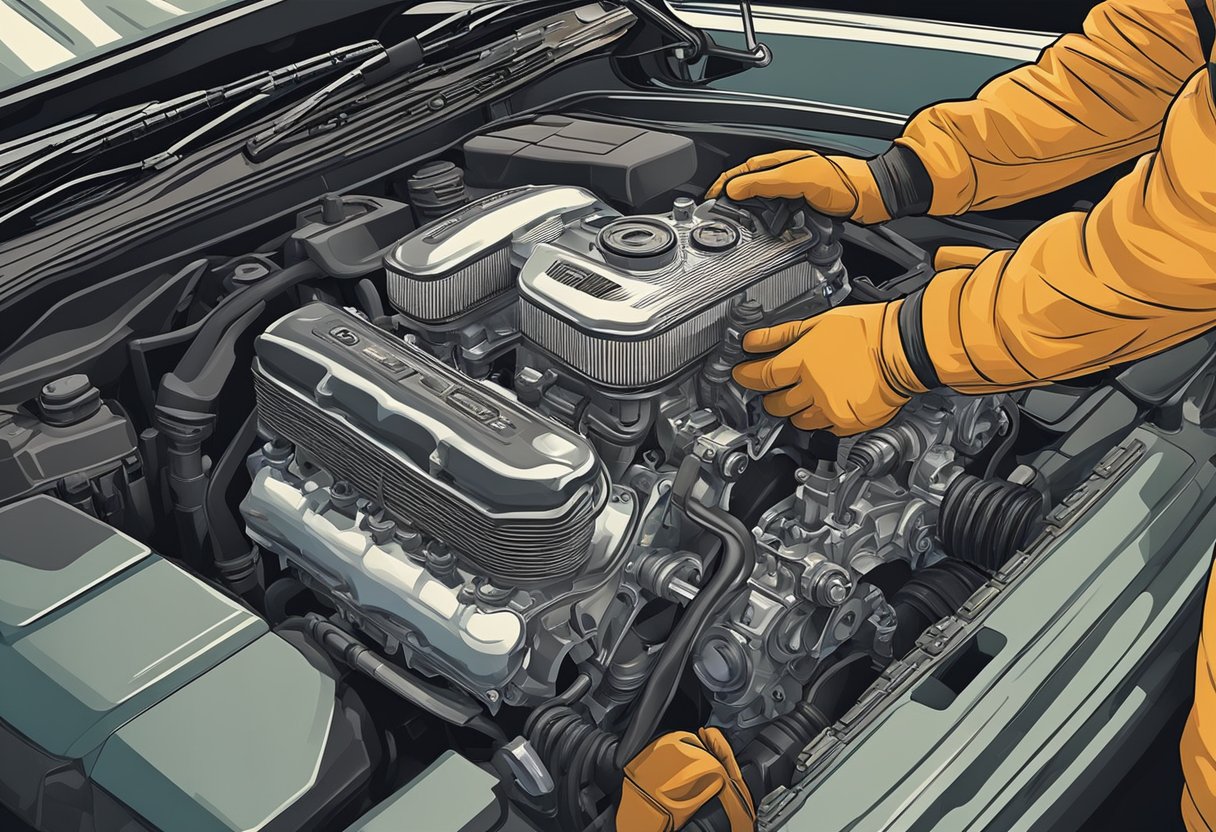

Diagnostic Techniques

When diagnosing a faulty rocker arm, mechanics typically begin with a visual inspection for any signs of wear on the components beneath the valve cover.

This includes checking for proper lubrication, radial movement, and the condition of gaskets and pushrods.

A diagnostic scanner can also be helpful in identifying error codes related to the valve train system. For engines with hydraulic lifters, checking for proper adjustments is also key. Unusual noises from the engine, often compared to that of a sewing machine, can pinpoint the need for further inspection of the rocker arms.

Tools and Materials

Repairing a rocker arm typically requires a range of tools and materials. Necessary items include:

- Wrenches and socket sets

- Torque wrench

- New rocker arms and hydraulic lifters if necessary

- Replacement gaskets for the valve cover and cylinder head

- Guide plates and pushrods

- Timing chain or belt tools if camshaft removal is needed

- Spark plug socket

- Gasket sealant and lubricants

While some repairs can be a simple matter of adjustment and replacement of individual parts, others may require the disassembly of significant engine components, including the cylinder head or camshaft. The complexity of rocker arm repair can vary greatly between SOHC and DOHC engines due to the number and accessibility of rockers.

Rocker Arm Replacement Costs

The cost of replacing a rocker arm can vary widely depending on the vehicle’s make and model, the type of materials used in the rocker arms, and the labor charges. Below is a breakdown of these costs into labor and parts, detailing various factors that can influence the overall repair bill.

Calculating Replacement Costs

Labor costs are a significant part of rocker arm replacement, typically ranging from $80 to $200 per hour. The total hours needed can depend on the complexity of the engine’s design, especially in vehicles with overhead cams or a V8 engine configuration.

For the rocker arms themselves, costs can differ if they’re made from stamped steel, aluminum, or forged carbon steel. Buyers can expect to pay anywhere from $15 to $30 for each rocker arm, with some needing additional components like dow pins or a throttle body for proper installation.

Total parts packages, including essential extras like valve cover gaskets or pushrods, may cost between $180 to $300.

Potential Additional Expenses

When replacing a rocker arm, additional parts may be necessary, such as a new valve cover gasket or even an air cleaner if the existing one has been contaminated by engine misfires or oil changes gone awry.

The appearance of a check engine light might signal a P2646 or P2647 code, which often relates to rocker arm issues in cars with more technical engine configurations like V8 models or those with overhead cams. In such cases, addressing fuel problems or a faulty throttle body might add to the repair bill.

It’s important for car owners to be aware that costs will also be influenced by their choice of mechanic—whether it’s a local Chrysler technician or a more generic service provider.

Finally, the technical know-how required to correctly torque each component with a torque wrench further underscores the importance of professional intervention, which while adding cost, can ensure the longevity of the repair.

As an Amazon Associate we earn from qualifying purchases.

My car has started to make a clicking noise under the hood recently, and I’m starting to worry it might be the rocker arm issue you’ve mentioned. Could a regular maintenance check have prevented this problem, or is it something that occurs with wear and tear regardless of maintenance?