If your car’s HVAC system is not working properly, it could be due to a faulty blower motor resistor. The blower motor resistor controls the speed of the blower motor in your car’s heating and air conditioning system. If it fails, your system may only work on certain speeds or not at all. In this article, we will discuss how to test and fix a blower motor resistor in your vehicle.

Testing your blower motor resistor is the first step in determining if it is faulty. You can use a multimeter to test the resistance of each of the resistors in the blower motor resistor. If the resistance is not within the manufacturer’s specifications, you may need to replace the resistor. It is important to note that the testing procedure may vary depending on the make and model of your vehicle.

If your blower motor resistor is faulty, you may be able to fix it yourself. In some cases, the resistor may simply need to be cleaned or have a bad connection repaired. However, if the resistor is damaged or worn out, it will need to be replaced. Replacement parts can be found at most auto parts stores or online. With the right tools and knowledge, you can fix your blower motor resistor and have your HVAC system working like new again.

Understanding Blower Motor Resistors

Blower motor resistors are an essential component of the HVAC system in your car. They play a crucial role in regulating the airflow through the system, which is essential for maintaining a comfortable temperature inside your vehicle. In this section, we will discuss the role and function of blower motor resistors, the different types of resistors, and their key components.

Role and Function

The blower motor resistor is responsible for controlling the speed of the blower motor in your car’s HVAC system. It works by regulating the amount of electrical current that flows through the fan motor. The resistor does this by varying the resistance of the coil. The higher the resistance, the less current flows through the motor, which results in a slower fan speed. Conversely, the lower the resistance, the more current flows through the motor, resulting in a higher fan speed.

Common Types of Resistors

There are two common types of blower motor resistors: linear and pulse width modulation (PWM) resistors. Linear resistors are the most common type and are used in systems where the blower motor has only a few fixed speeds. PWM resistors, on the other hand, are used in systems where the motor can be controlled continuously. PWM resistors are more efficient than linear resistors because they reduce the amount of power that is wasted as heat.

Key Components

The key components of a blower motor resistor include the power transistor, the coils, and the control module. The power transistor is responsible for regulating the amount of current that flows through the motor. The coils are used to vary the resistance of the resistor, which controls the fan speed. The control module is responsible for receiving input from the HVAC system and adjusting the fan speed accordingly.

Overall, blower motor resistors are an essential component of your car’s HVAC system. They play a crucial role in regulating the airflow through the system, which is essential for maintaining a comfortable temperature inside your vehicle. Understanding how they work and the different types of resistors available can help you diagnose and fix any issues you may encounter with your HVAC system.

Symptoms of a Faulty Blower Motor Resistor

The blower motor resistor is an important component of your vehicle’s heating, ventilation, and air conditioning (HVAC) system. It controls the speed of the blower motor fan, which is responsible for circulating air through the cabin of your vehicle. If the blower motor resistor fails, you may experience a number of symptoms that can affect your comfort and safety while driving.

Inconsistent Fan Speed

One of the most common symptoms of a faulty blower motor resistor is an inconsistent or intermittent fan speed. The fan may work fine at low speeds but fail to work at higher speeds, or it may work fine at high speeds but fail to work at low speeds. This can make it difficult to maintain a comfortable temperature in your vehicle, especially during extreme weather conditions.

No Air from Vents

Another symptom of a faulty blower motor resistor is no air coming from the vents. If the resistor fails, the blower motor fan may not work at all, which means that no air will circulate through the cabin of your vehicle. This can be a serious safety issue, especially if you are driving in extreme weather conditions.

Overheating Issues

In some cases, a faulty blower motor resistor can cause overheating issues. If the resistor fails, the blower motor fan may continue to run even when the engine is turned off, which can drain the battery and cause the engine to overheat. This can lead to serious engine damage and should be addressed immediately.

If you experience any of these symptoms, it’s important to have your blower motor resistor checked by a qualified mechanic. They can diagnose the problem and recommend the appropriate repairs to ensure that your HVAC system is working properly.

Testing the Blower Motor Resistor

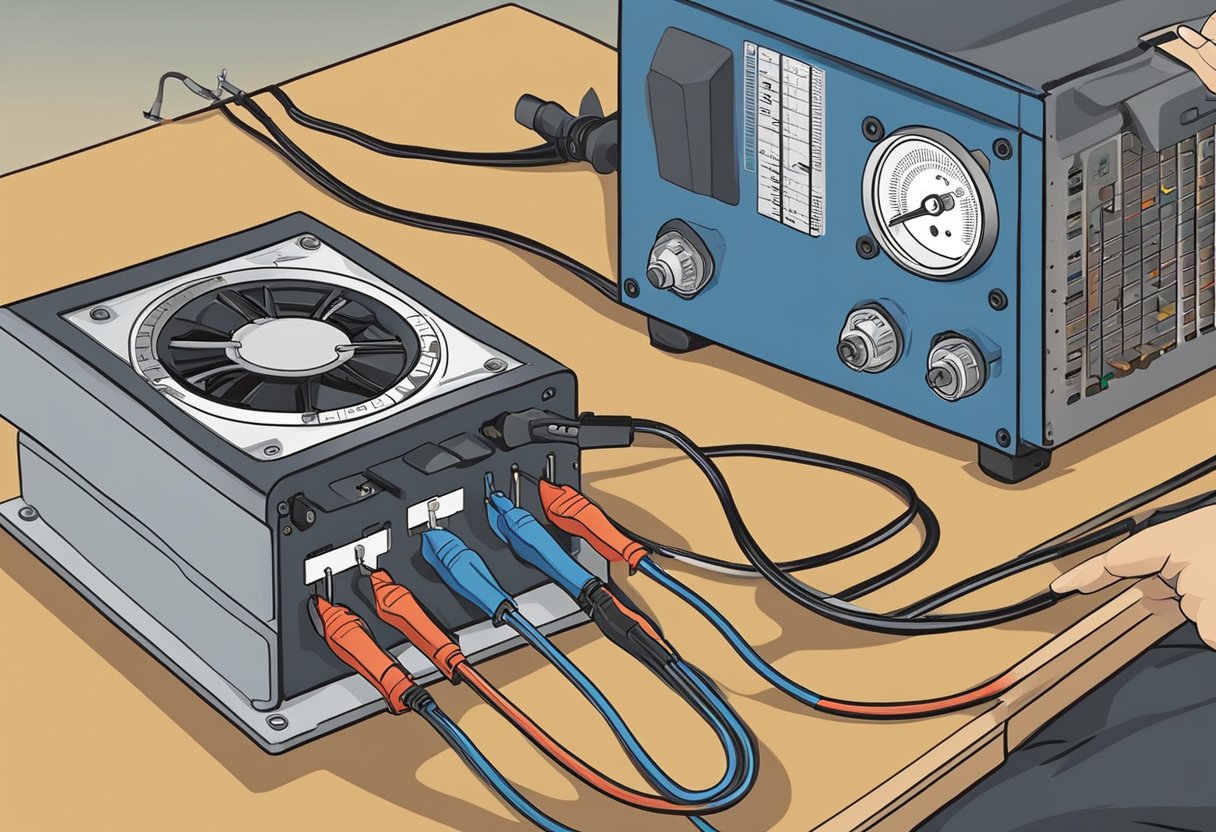

When your car’s blower motor fails to work, it could be due to a faulty blower motor resistor. Testing the blower motor resistor is a straightforward process that you can do with a multimeter. Here are the steps to follow:

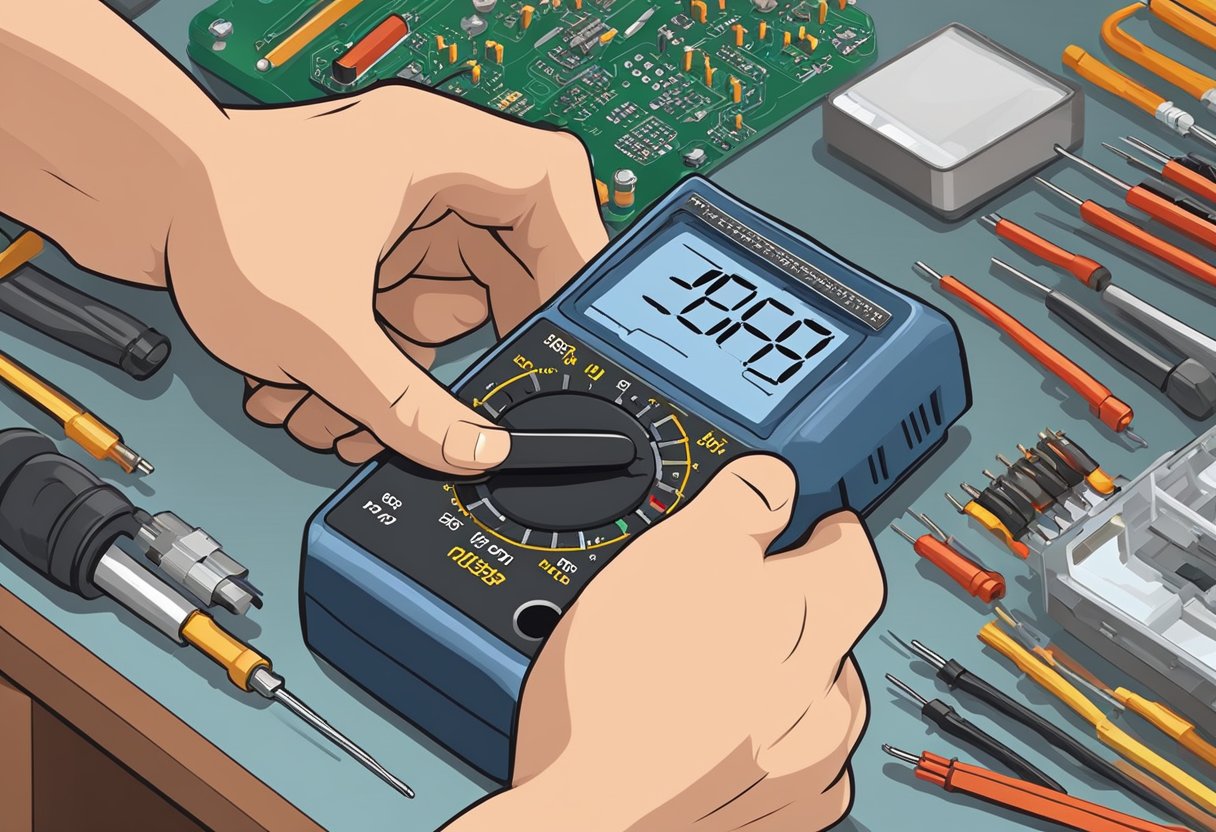

Using a Multimeter

-

Start by locating the blower motor resistor. It is usually located in the HVAC system, close to the blower motor. In some older cars, it may be installed on the firewall with access from under the hood.

-

Disconnect the electrical connector from the blower motor resistor.

-

Set your multimeter to ohms mode.

-

Connect the multimeter probes to the terminals of the connector. The specific terminals to check will depend on your car’s make and model. Refer to your car’s repair manual for the correct terminals to check.

-

Check the resistance value of each terminal. If the resistance value is outside the manufacturer’s specifications, then the blower motor resistor is faulty and needs to be replaced.

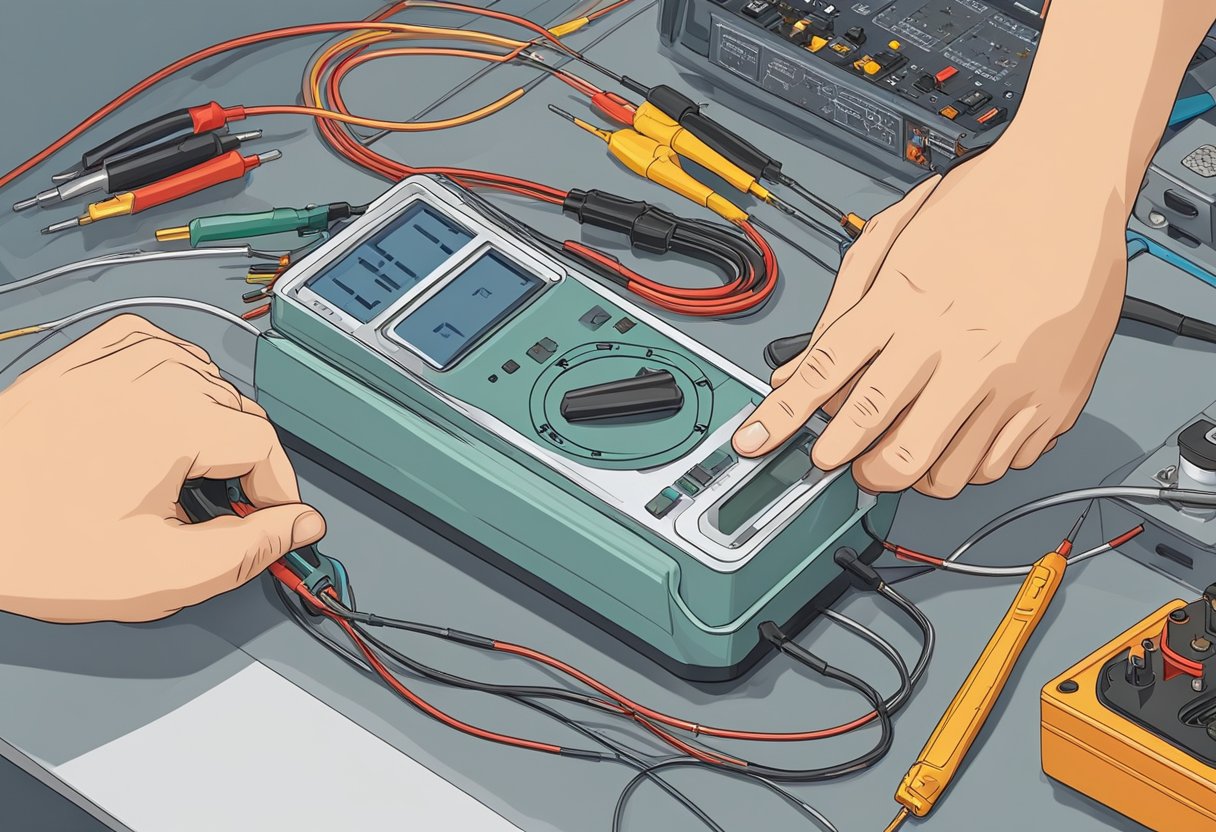

Continuity Test

Another way to test the blower motor resistor is to perform a continuity test. Here are the steps to follow:

-

Disconnect the electrical connector from the blower motor resistor.

-

Set your multimeter to continuity mode.

-

Connect one multimeter probe to one of the terminals of the connector.

-

Touch the other multimeter probe to the other terminals of the connector one by one. If you get a beep or a continuity reading, then the blower motor resistor is working correctly. If you don’t get a beep or a continuity reading, then the blower motor resistor is faulty and needs to be replaced.

Visual Inspection

You can also perform a visual inspection of the blower motor resistor to check for corrosion or other damage. Here are the steps to follow:

-

Disconnect the electrical connector from the blower motor resistor.

-

Inspect the terminals and connector for any signs of corrosion or damage.

-

If you find any corrosion or damage, then the blower motor resistor is faulty and needs to be replaced.

Testing the blower motor resistor is crucial in diagnosing and fixing blower motor problems. By following these steps, you can determine if the blower motor resistor is faulty and needs to be replaced.

Can Blower Motor Resistors Cause Windshield Wipers to Malfunction?

When troubleshooting windshield wipers malfunctions, it’s important to consider the blower motor resistors. Faulty resistors can indeed cause issues with the windshield wipers, leading to erratic movements or complete failure. Identifying and replacing the problem resistor can be the fix needed to restore proper wiper function.

Troubleshooting and Repair

Identifying Electrical Issues

When your blower motor isn’t working correctly, it could be due to a problem with the blower motor resistor or another electrical issue. Before you start replacing parts, you should troubleshoot the problem to identify the root cause. Here are a few things to check:

- Fuse – Check the fuse that controls the blower motor resistor. If the fuse is blown, replace it and test the blower motor again.

- Wiring Diagram – Refer to the wiring diagram for your vehicle to ensure that the blower motor resistor is wired correctly.

- Circuit – Use a multimeter to test the circuit and ensure that there is continuity.

- Defective Parts – Test the blower motor resistor and other electrical components to determine if they are defective.

By checking these things, you can identify the cause of the electrical issue and determine what needs to be fixed or replaced.

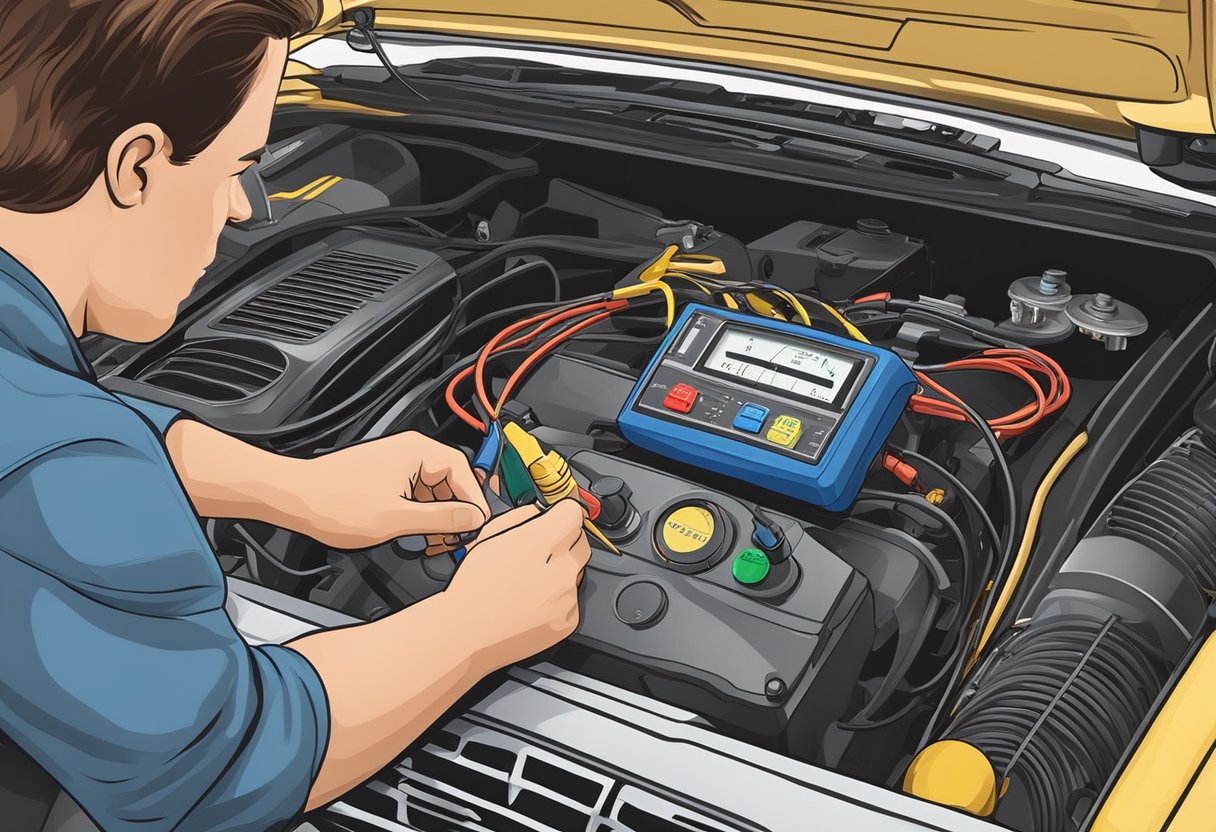

Replacing the Resistor

If you’ve determined that the blower motor resistor is the problem, you’ll need to replace it. Here are the steps to follow:

- Disconnect the Battery – Before you start working on any electrical components, disconnect the battery to ensure your safety.

- Locate the Resistor – The blower motor resistor is typically located near the blower motor. Refer to your vehicle’s service manual or wiring diagram if you’re unsure where to find it.

- Remove the Old Resistor – Use a screwdriver to remove the screws holding the old resistor in place. Carefully disconnect any wires connected to the resistor.

- Install the New Resistor – Connect the wires to the new resistor and secure it in place with screws.

- Reconnect the Battery – Reconnect the battery and test the blower motor to ensure that it’s working correctly.

By following these steps, you can replace the blower motor resistor and restore your vehicle’s heating and cooling system to working order.

Advanced Diagnostics

When basic diagnostics fail to identify the root cause of the blower motor resistor problem, advanced diagnostics come into play. In this section, we will discuss two advanced diagnostic methods that can help you identify the problem with your blower motor resistor.

Automatic Climate Control Systems

Automatic climate control systems are equipped with an electronic control module that controls the blower motor resistor. These systems are more complex than manual systems and require specialized diagnostic tools to identify the problem.

Utilizing a Scan Tool

A scan tool is a specialized diagnostic tool that can be used to diagnose problems with the blower motor control module. It can read fault codes and provide real-time data from the electronic control module. When using a scan tool, you can check the system’s parameters such as the voltage and current levels, which can help you to identify the problem with the blower motor resistor.

When you connect the scan tool to the system, it will give you a list of fault codes that can help you to identify the problem. Once you have identified the problem, you can then use the scan tool to clear the fault codes and reset the system.

In conclusion, advanced diagnostics are necessary when basic diagnostics fail to identify the root cause of the blower motor resistor problem. By utilizing automatic climate control systems and scan tools, you can diagnose the problem with the blower motor resistor accurately and efficiently.

As an Amazon Associate we earn from qualifying purchases.