If you’re experiencing engine problems, one possible culprit could be a faulty knock sensor. This component is responsible for detecting vibrations and noises in the engine caused by detonation or pre-ignition. When the knock sensor fails, it can lead to a host of issues, including poor performance, reduced fuel efficiency, and even engine damage.

Fortunately, there are several symptoms that can alert you to a potential knock sensor problem. These may include a decrease in power and acceleration, unusual engine noises, and a decrease in fuel efficiency. If you’re experiencing any of these issues, it’s important to have your vehicle inspected by a qualified mechanic who can diagnose the problem and recommend the appropriate course of action.

In this article, we’ll take a closer look at the symptoms of knock sensor failure and explore some of the methods used to test for this issue. Whether you’re a seasoned mechanic or a car owner looking to troubleshoot engine problems, this guide will provide you with the information you need to identify and address knock sensor issues in your vehicle.

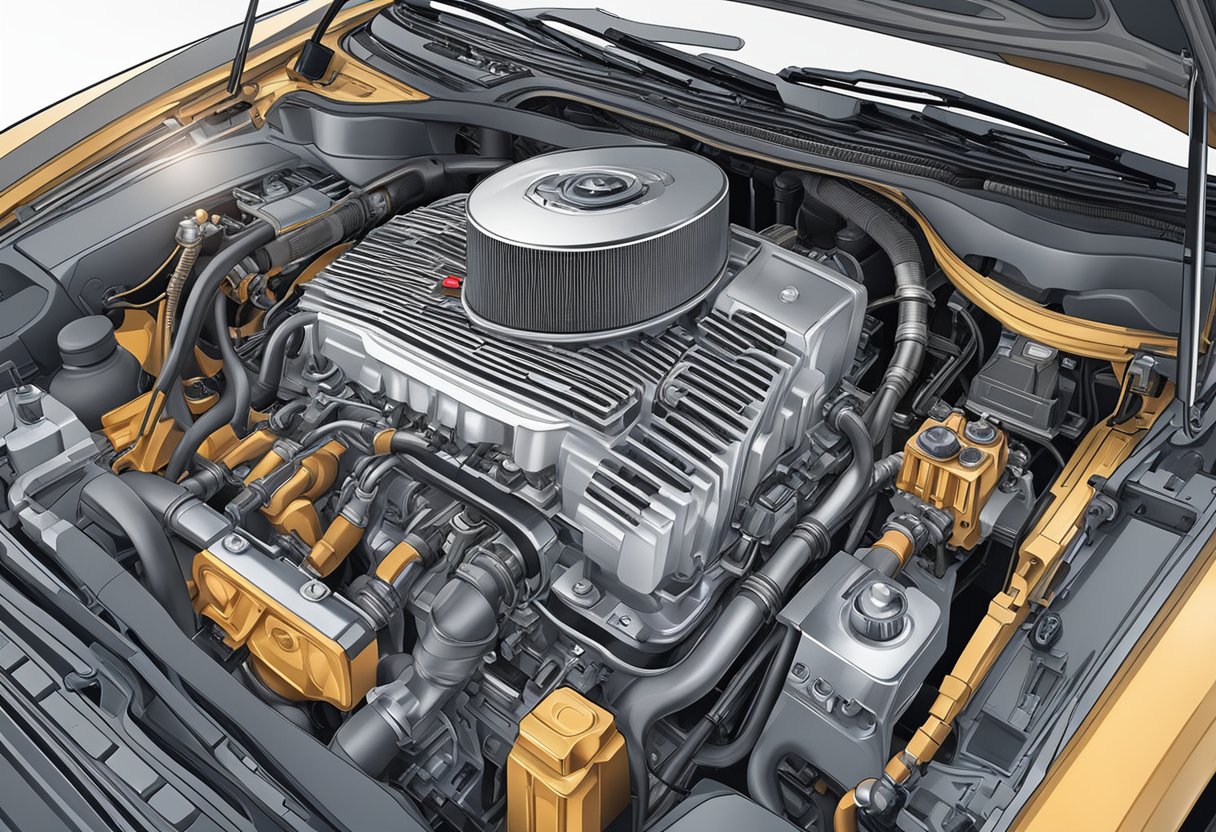

Understanding Knock Sensors

Function of a Knock Sensor

A knock sensor is an essential component of an engine management system that detects the presence of engine knock or detonation. Engine knock is a phenomenon that occurs when the air/fuel mixture in the combustion chamber ignites spontaneously before the spark plug fires. This can cause damage to the engine if left unchecked. The knock sensor is designed to detect these vibrations and send a signal to the engine control module (ECM) to adjust the timing and prevent engine knock.

Importance of Knock Sensor in Engine Management

The knock sensor plays a crucial role in engine management by ensuring that the engine runs smoothly and efficiently. If the knock sensor fails, the ECM will not be able to detect engine knock, which can lead to engine damage and reduced performance. In some cases, the ECM may even retard the timing excessively to prevent engine knock, which can result in decreased power and fuel economy.

To ensure that your engine is running at its best, it’s important to test the knock sensor periodically. This can be done using a multimeter or an oscilloscope to measure the sensor’s output voltage. If the voltage is outside of the manufacturer’s specifications, the knock sensor may need to be replaced.

In summary, the knock sensor is a critical component of an engine management system that helps to prevent engine knock and ensure optimal performance. Regular testing and maintenance of the knock sensor can help to keep your engine running smoothly and efficiently.

Symptoms of Knock Sensor Failure

If your vehicle’s knock sensor fails, it can cause a variety of issues that can affect your car’s performance. Here are some common symptoms of knock sensor failure that you should be aware of:

Check Engine Light Activation

One of the most common symptoms of a knock sensor failure is the activation of the check engine light. The knock sensor is responsible for detecting any unusual engine noises, and if it fails, it will send an error code to your car’s computer, which will activate the check engine light on your dashboard.

Poor Engine Performance

Another symptom of knock sensor failure is poor engine performance. When the knock sensor fails, it can cause the engine to misfire, which can lead to a decrease in power and acceleration. You may also notice that your car is sluggish and unresponsive when you try to accelerate.

Decreased Fuel Efficiency

If your car’s knock sensor fails, it can also cause a decrease in fuel efficiency. This is because the engine will not be running as efficiently as it should be, which can lead to increased fuel consumption. You may notice that you need to fill up your gas tank more frequently than usual.

Unusual Engine Noises

Finally, a failed knock sensor can also cause unusual engine noises. This is because the knock sensor is responsible for detecting any unusual sounds coming from the engine, and if it fails, it may not be able to detect these sounds. As a result, you may hear knocking or pinging sounds coming from your engine, which can be a sign of serious engine damage.

In conclusion, if you notice any of these symptoms, it’s important to have your car checked by a professional mechanic as soon as possible to diagnose and fix the issue.

What Are the Symptoms of Knock Sensor Failure and How Can I Test for It?

When it comes to diagnosing low input knock sensor failure, it’s important to pay attention to certain symptoms. These can include engine hesitation, a decrease in fuel efficiency, and unusual engine noises. To test for it, you can use a diagnostic tool to check for trouble codes and conduct a visual inspection of the sensor.

Testing the Knock Sensor

When you suspect your knock sensor is failing, it is important to test it to confirm the problem. Testing your knock sensor requires a few tools and a basic understanding of your vehicle’s electrical system. In this section, we will discuss how to test your knock sensor using a visual inspection, electrical test procedure, and diagnostic trouble codes analysis.

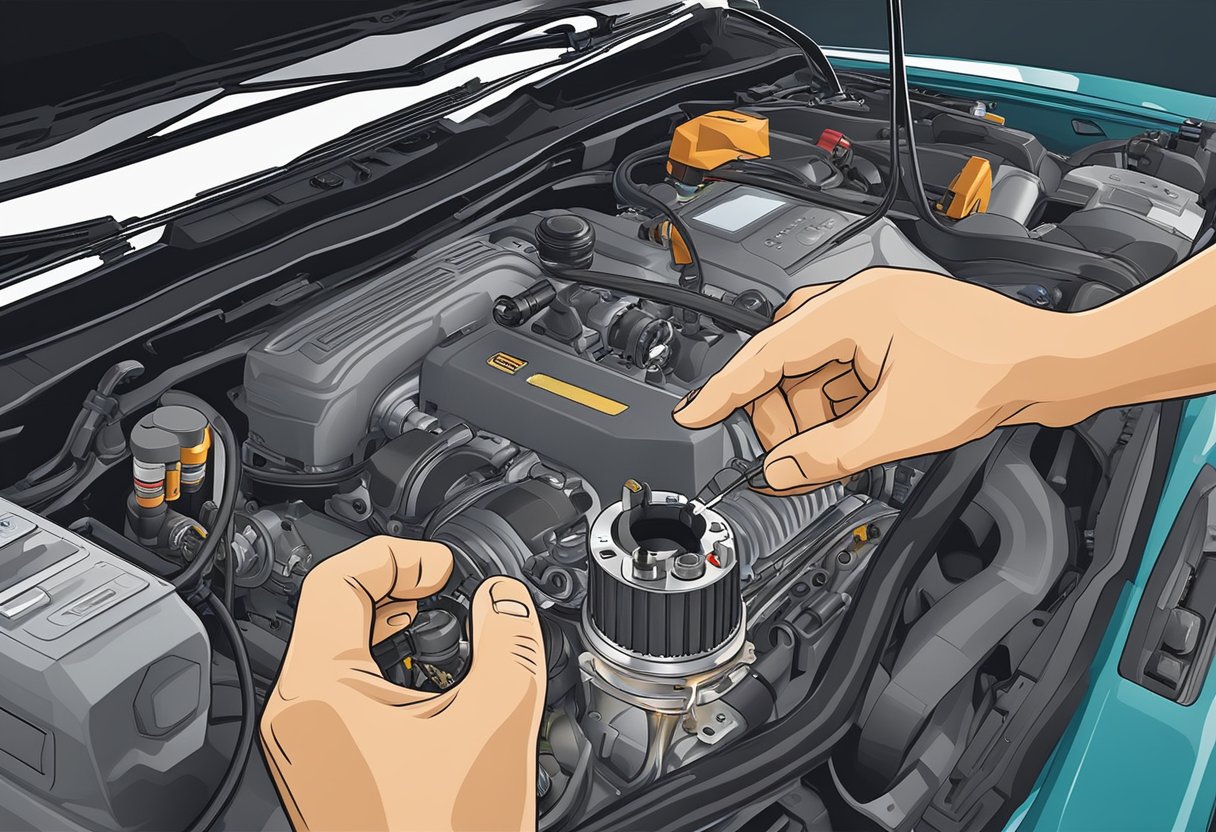

Visual Inspection

Before testing your knock sensor, you should first perform a visual inspection to check for any physical damage or corrosion. Inspect the sensor and its wiring harness for any damage or loose connections. If the sensor or wiring harness is damaged, it may need to be replaced. Also, check for any signs of oil or coolant leaks, as these can damage the sensor.

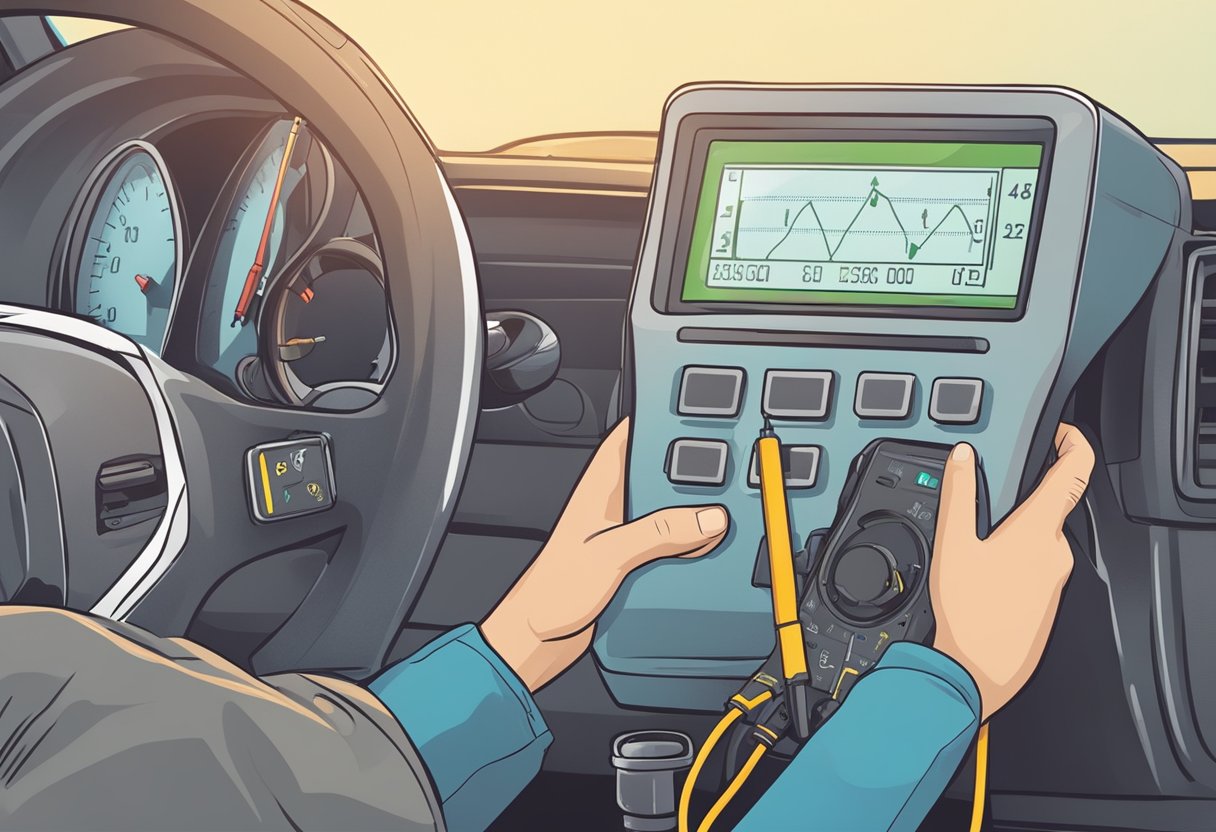

Electrical Test Procedure

To perform an electrical test on your knock sensor, you will need a digital multimeter. Follow these steps to test your knock sensor:

- Locate the knock sensor on your vehicle. It is usually located on the engine block or cylinder head.

- Disconnect the electrical connector from the knock sensor.

- Set your multimeter to measure resistance (ohms).

- Connect the multimeter leads to the two pins on the knock sensor.

- Check the resistance reading on the multimeter. The resistance should be within the manufacturer’s specifications. If the resistance is outside of the specified range, the knock sensor may be faulty and need to be replaced.

Diagnostic Trouble Codes Analysis

If your vehicle’s check engine light is on, you can use a diagnostic scanner to check for any trouble codes related to the knock sensor. Follow these steps to check for trouble codes:

- Connect the diagnostic scanner to your vehicle’s OBD-II port.

- Turn on the ignition but do not start the engine.

- Follow the scanner’s instructions to read any trouble codes.

- Look for any codes related to the knock sensor, such as P0325 or P0330.

- If there are any trouble codes related to the knock sensor, it may be faulty and need to be replaced.

In conclusion, testing your knock sensor requires a visual inspection, electrical test procedure, and diagnostic trouble codes analysis. By following these steps, you can confirm whether your knock sensor is faulty and needs to be replaced.

What Are the Symptoms of Knock Sensor Failure and How Can It Be Tested?

Recognizing bad O2 sensor symptoms can help diagnose knock sensor failure. Common signs include poor engine performance, reduced fuel efficiency, and an illuminated check engine light. To test for knock sensor failure, a mechanic can use a scanner to check for trouble codes and perform a voltage test on the sensor.

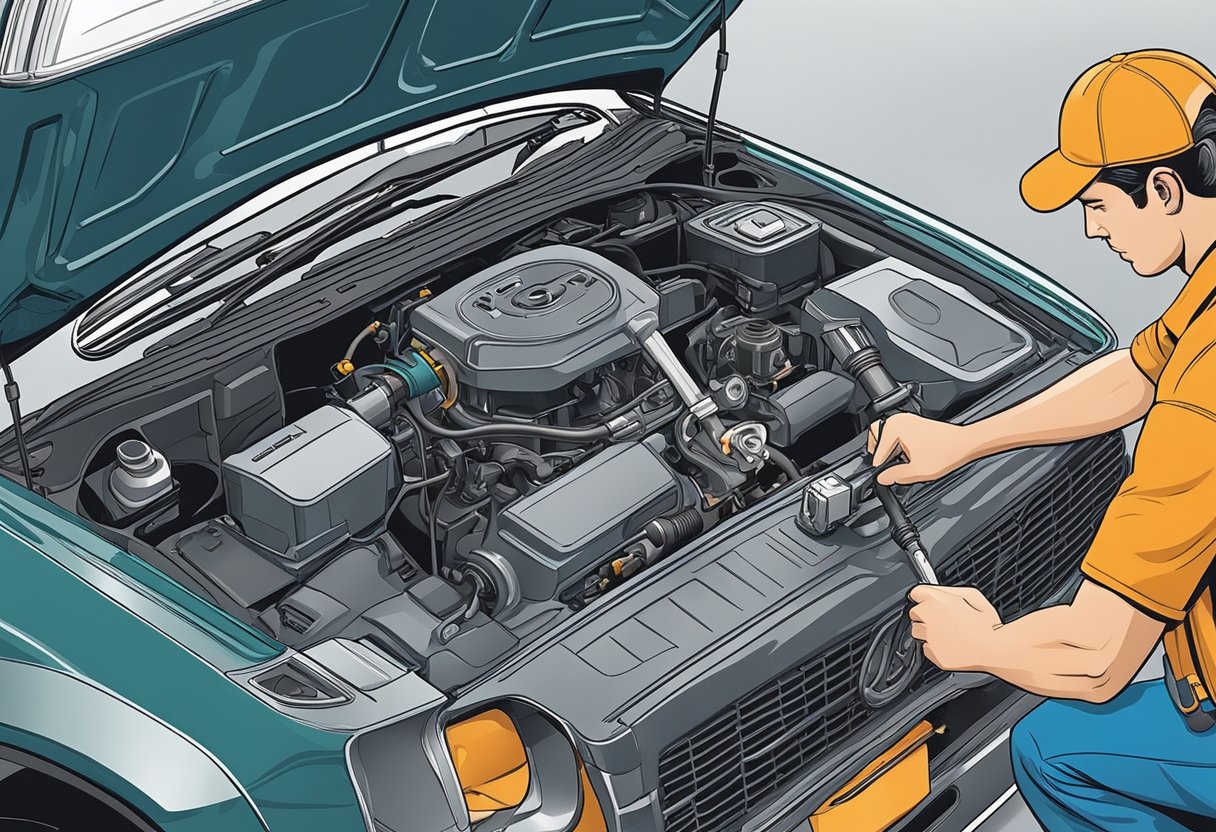

Replacing a Faulty Knock Sensor

Tools and Materials Required

Before replacing a faulty knock sensor, you will need the following tools and materials:

- Socket wrench

- Socket set

- New knock sensor

- Torque wrench

- Cleaning solution

- Rag

Step-by-Step Replacement Guide

Here is a step-by-step guide to replacing a faulty knock sensor:

- Locate the knock sensor. It is usually located on the engine block or cylinder head.

- Disconnect the electrical connector from the sensor.

- Remove the sensor using a socket wrench and socket set. Be careful not to damage the sensor or the surrounding area.

- Clean the area around the sensor with a cleaning solution and a rag. Make sure there is no debris or dirt left behind.

- Install the new knock sensor and tighten it to the manufacturer’s specifications using a torque wrench.

- Reconnect the electrical connector to the sensor.

- Start the engine and check for any warning lights or abnormal engine noises.

Replacing a faulty knock sensor is a straightforward process that can be done with basic tools and materials. By following these steps, you can ensure that your engine is running smoothly and efficiently.

Preventive Measures and Maintenance Tips

To prevent knock sensor failure, it is important to maintain your vehicle properly. Here are some tips to help you avoid knock sensor issues:

- Regularly change your engine oil and oil filter as per the manufacturer’s recommendations. Dirty oil can cause engine knock, which can damage the knock sensor.

- Keep your engine coolant at the proper level and change it as recommended by the manufacturer. Overheating can cause knock sensor failure.

- Avoid using low-quality gasoline. Poor quality fuel can cause engine knock, which can damage the knock sensor.

- Keep your air filter clean. A dirty air filter can cause a rich fuel mixture, which can lead to engine knock and knock sensor failure.

- Do not ignore any warning signs of engine knock, such as a knocking sound or a check engine light. Addressing these issues promptly can prevent further damage to the knock sensor.

Regular maintenance and prompt attention to any issues can help prevent knock sensor failure and ensure the longevity of your vehicle.

As an Amazon Associate we earn from qualifying purchases.