Learning how to properly install spark plugs is crucial for maintaining your vehicle’s performance. One of the most important aspects of spark plug installation is ensuring that they are tightened to the correct torque. This is because spark plugs that are either too loose or too tight can cause serious problems for your engine.

When it comes to spark plug torque, there is no one-size-fits-all answer. The torque specifications for your spark plugs will vary depending on your vehicle’s make and model. To find the correct torque for your spark plugs, you can consult your vehicle’s owner’s manual or a repair manual. Also, many manufacturers provide torque specifications for their spark plugs on their websites.

Understanding Spark Plug Basics

To learn the right torque for spark plugs, it is essential to understand the basics of spark plugs. Spark plugs are a crucial component of your vehicle’s engine, responsible for igniting the air-fuel mixture in the combustion chamber. They are a “window” into the engine, providing valuable information about engine performance and combustion.

Types of Spark Plugs

Spark plugs come in different types, including copper, nickel, platinum, and iridium spark plugs. Copper spark plugs are the most affordable and have a shorter lifespan compared to other types. Nickel spark plugs are an improvement over copper spark plugs and have a longer lifespan. Platinum spark plugs are more expensive than nickel spark plugs and have a longer lifespan.

Iridium spark plugs are the most expensive and have the longest lifespan. They are the best option for modern engines that require high-performance spark plugs. They have a smaller center electrode, which reduces the required voltage and improves engine performance.

Role of Spark Plugs in Combustion

Spark plugs play a crucial role in combustion. They ignite the air-fuel mixture in the combustion chamber, which creates a controlled explosion that powers the engine. The spark plug’s heat range is crucial for proper combustion. The heat range refers to the spark plug’s ability to dissipate heat from the combustion chamber.

If the spark plug’s heat range is too hot, it can cause pre-ignition, which damages the engine. If the spark plug’s heat range is too cold, it can cause fouling, which reduces engine performance. Therefore, it is essential to choose the right spark plug heat range for your vehicle.

In conclusion, understanding spark plug basics is crucial to learn the right torque for spark plugs. There are different types of spark plugs, including copper, nickel, platinum, and iridium spark plugs. The spark plug’s role in combustion is to ignite the air-fuel mixture in the combustion chamber, creating a controlled explosion that powers the engine. The spark plug’s heat range is crucial for proper combustion, and it is essential to choose the right heat range for your vehicle.

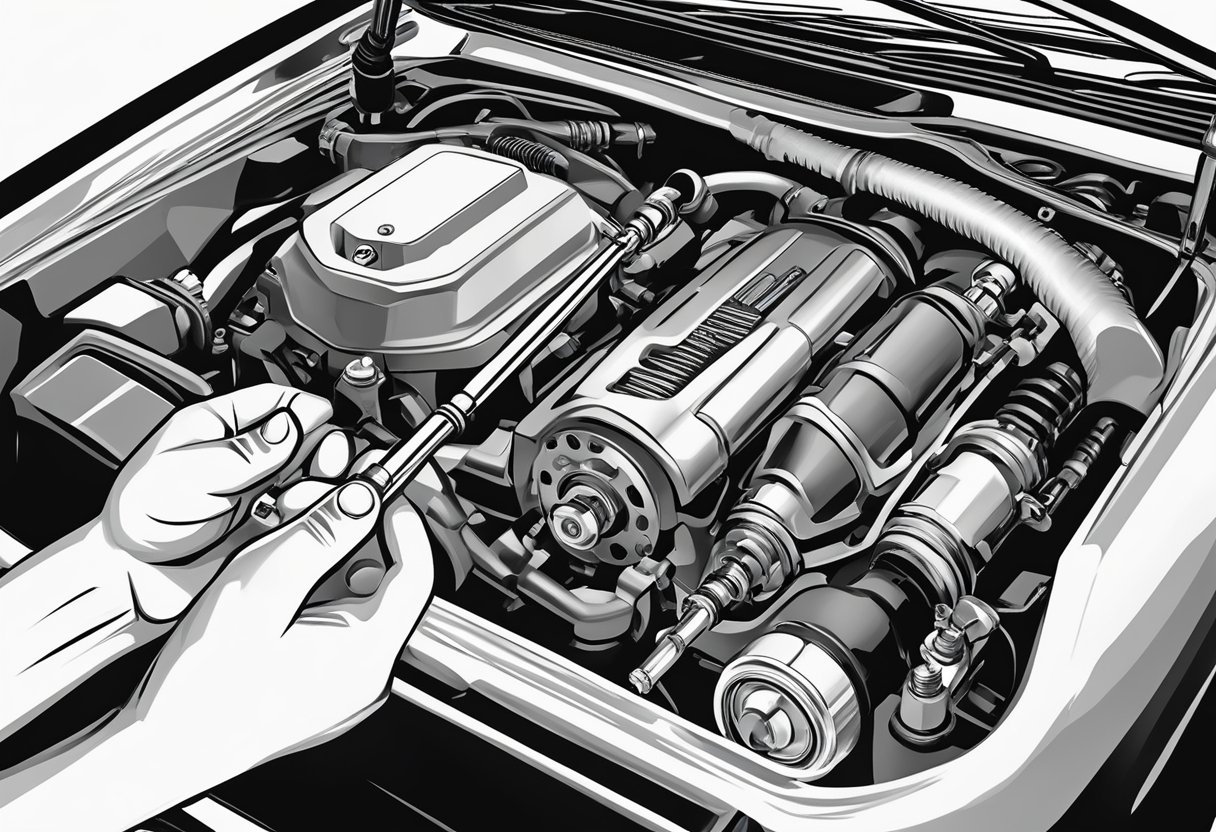

Tools and Preparation

Before you start the process of tightening your spark plugs, you need to make sure you have the right tools and are properly prepared.

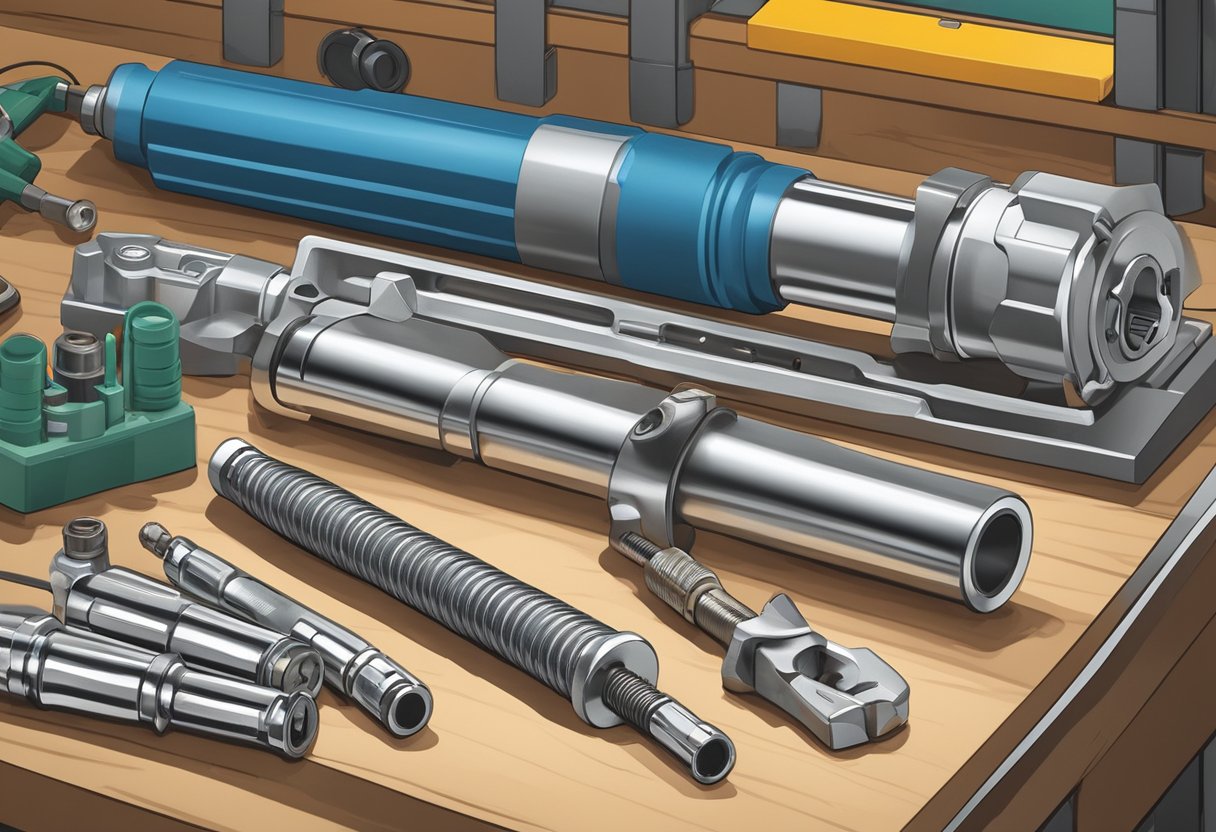

Selecting the Right Torque Wrench

The first tool you need is a torque wrench. It’s important to select the right size of torque wrench for your spark plugs. Most vehicles will require either a 3/8 inch or 1/2 inch torque wrench. A 1/2 inch torque wrench is capable of handling the most major and common repairs, so it is sufficient to meet your spark plug needs. You can find torque wrenches at many price points and in socket-drive sizes of 1/4, 3/8, 1/2, 3/4, and 1 inch.

Preparation of Spark Plug and Cylinder Head

Before you start, make sure your engine is cool. You don’t want to work on a hot engine as it can be dangerous. Next, remove the spark plug wire from the spark plug by pulling on the boot. Make sure you don’t pull on the wire itself as it can damage the wire. Then, use a spark plug socket to remove the spark plug. Make sure you have the right size socket for your spark plugs. You can check your vehicle’s manual or use an online repair database to find the right size.

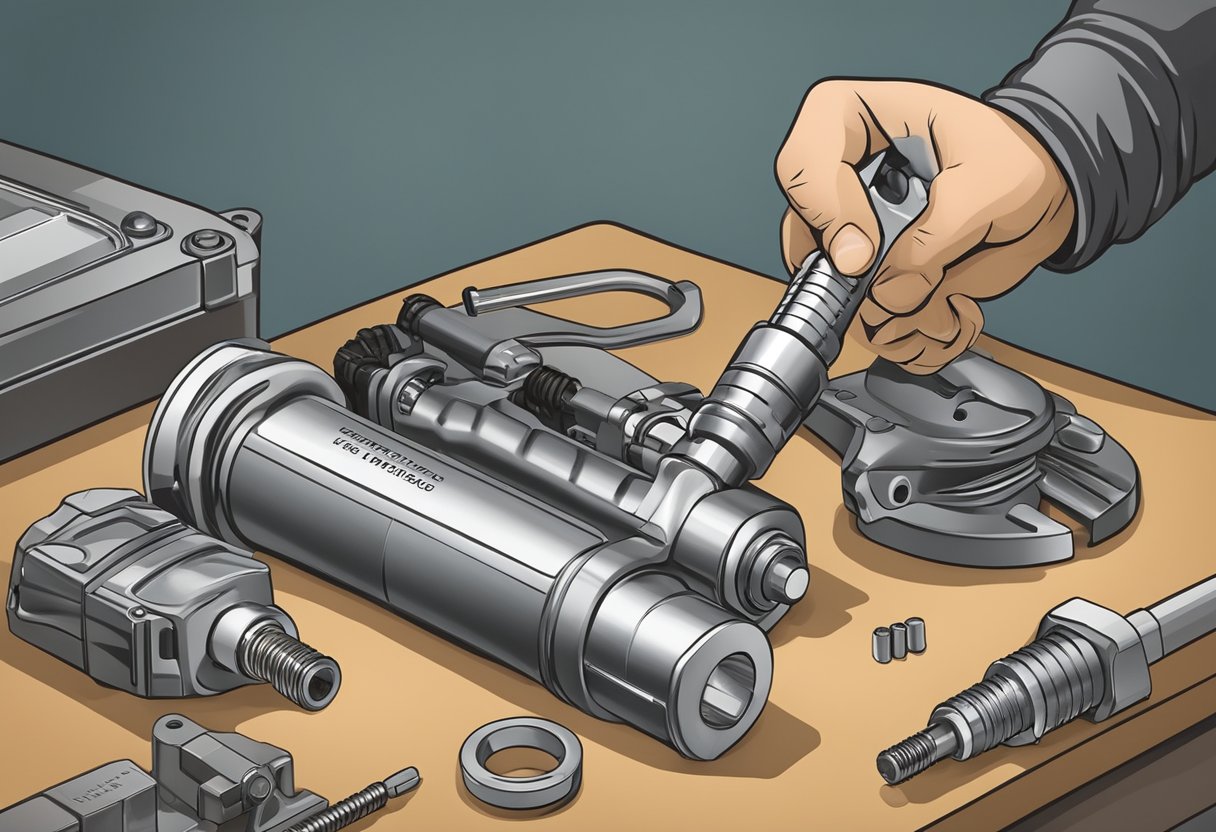

Once you have removed the spark plug, inspect it for any damage or wear. If it looks worn or damaged, you should replace it with a new one. Next, apply a small amount of anti-seize to the threads of the new spark plug. This will help prevent the spark plug from seizing in the cylinder head. Make sure you don’t apply too much anti-seize as it can cause the spark plug to over-torque.

Finally, lubricate the spark plug threads with a small amount of oil or anti-seize. This will help ensure a smooth and easy installation. Insert the spark plug into the cylinder head and tighten it by hand until it is snug. Then, use your torque wrench to tighten the spark plug to the manufacturer’s recommended torque specification.

By selecting the right tools and properly preparing your spark plugs and cylinder head, you can learn the right torque for your spark plugs and ensure a successful installation.

The Importance of Correct Torque

When it comes to spark plugs, applying the correct torque is crucial to ensure a secure fastening. Failing to do so can lead to a range of issues, from engine damage to thread damage. In this section, we’ll explore the consequences of incorrect torque and why torque specifications matter.

Consequences of Incorrect Torque

Over-tightening or under-torquing your spark plugs can cause significant damage to your engine. Over-tightening can lead to thread damage, while under-torquing can cause the spark plug to loosen and eventually fall out. This can lead to serious engine damage, which can be costly to repair.

If you have an aluminum cylinder head, it is especially important to apply the correct torque. Aluminum is a soft metal and can easily be stripped if the spark plug is over-tightened. If you have a cast iron cylinder head, over-tightening can cause the threads to stretch and weaken, leading to potential thread damage.

Torque Specifications and Why They Matter

Torque specifications are the manufacturer’s recommended torque settings for a particular spark plug. These settings are based on the size and material of the spark plug, as well as the type of cylinder head. It is important to follow these specifications to ensure the proper installation of the spark plug.

Using a torque wrench is the most accurate way to achieve the correct installation torque setting. You can look up the torque specs in a repair manual or online repair database. It is important to note that different spark plugs require different amounts of torque, so there isn’t a one-size-fits-all answer to how tight spark plugs should be.

In conclusion, applying the correct torque when fitting spark plugs is essential to ensure a secure fastening and prevent engine damage. It is important to use a torque wrench and follow the manufacturer’s torque specifications to achieve the proper installation torque setting.

How Does TPS ‘A’ Circuit Range Performance Problem Affect Spark Plug Torque?

The TPS (throttle position sensor) plays a crucial role in an engine’s performance. When experiencing an OBDII trouble code for the TPS A circuit range performance problem, it can directly affect the spark plug torque. This can lead to poor engine performance and decreased fuel efficiency.

Does Learning the Torque for Spark Plugs Help Prevent Diagnostic Trouble Codes?

Learning the correct torque for spark plugs can help prevent bad spark plugs diagnostic trouble code. When spark plugs are not tightened to the right torque, it can cause misfires and trigger diagnostic trouble codes. Ensuring the proper torque can help maintain a secure connection and prevent potential issues.

How Does Understanding Torque for Spark Plugs Help in Tackling Random/Multiple Cylinder Misfires?

Understanding torque for spark plugs is crucial in tackling cylinder misfires. By ensuring the spark plugs are torqued to the manufacturer’s specifications, you can prevent random or multiple cylinder misfires. This tackling cylinder misfires article emphasizes the importance of proper torque to maintain optimal engine performance.

Step-by-Step Guide to Spark Plug Installation

Installing spark plugs is a simple task that can be done at home with the right tools and knowledge. In this guide, we will walk you through the step-by-step process of spark plug installation, including tightening the spark plugs to the correct torque.

Installing the Spark Plugs

Before installing new spark plugs, it’s important to check the gap between the electrodes with a feeler gauge to ensure they are the correct size. Once you have verified the gap, you can begin installing the spark plugs.

-

Start by removing the old spark plugs. Use a spark plug socket and ratchet to loosen the plugs and carefully remove them from the engine.

-

Apply a small amount of anti-seize lubricant to the threads of the new spark plugs. This will help prevent the plugs from seizing in the engine and make them easier to remove in the future.

-

Thread the new spark plugs into the engine by hand until they are snug. Be careful not to cross-thread the plugs, as this can damage the threads in the engine and cause leaks.

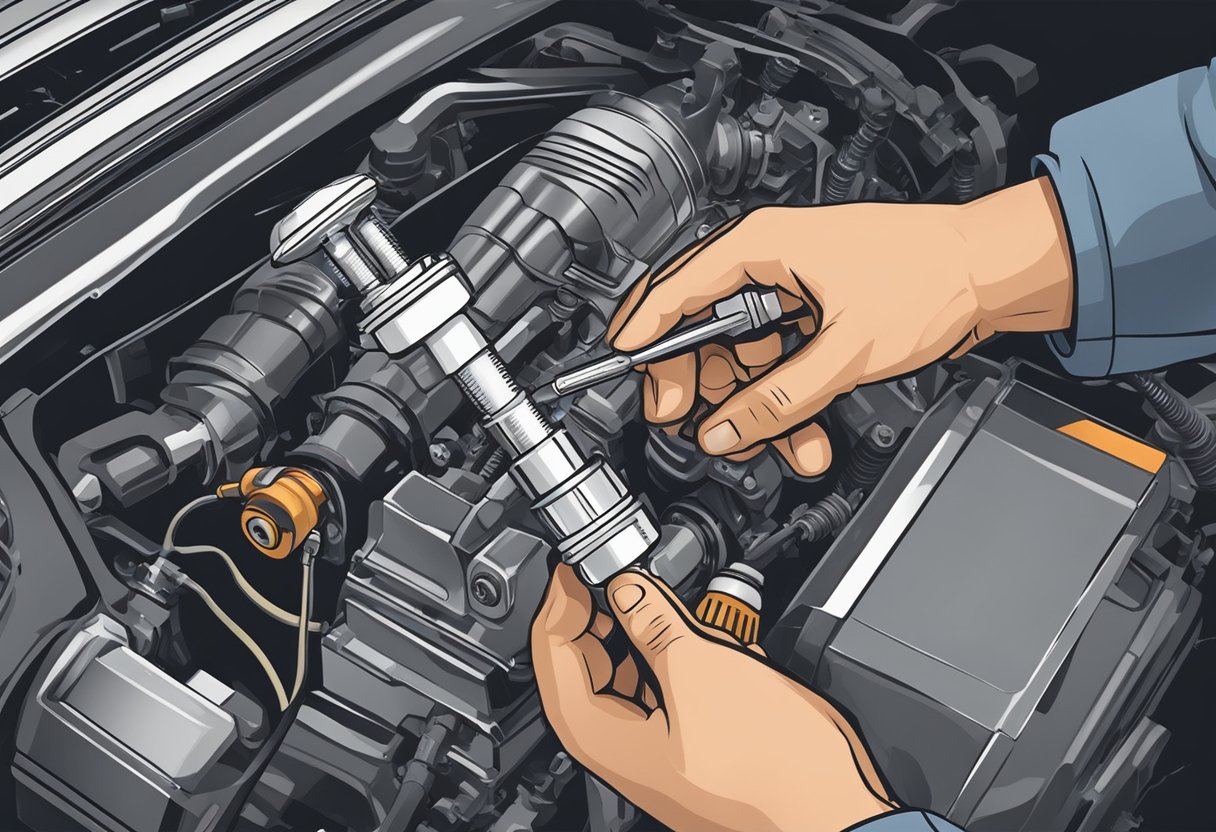

Tightening to the Right Torque

Tightening the spark plugs to the correct torque is crucial to ensure they are properly seated in the engine and to prevent damage to the threads or the plugs themselves. Here’s how to do it:

-

Refer to your vehicle’s owner’s manual or a torque specification chart, such as the one provided by Champion Auto Parts, to determine the correct torque for your spark plugs.

-

Use a torque wrench to tighten the spark plugs to the specified torque. Tighten them in a criss-cross pattern to ensure even torque distribution.

-

Once the spark plugs are tightened to the correct torque, reattach the spark plug wires and reinstall any other components that were removed during the installation process.

By following these simple steps, you can learn the right torque for spark plugs and install them with confidence. Remember to always consult your owner’s manual or a trusted source for torque specifications and other installation guidelines.

Troubleshooting Common Issues

When it comes to spark plug torque, there are a few common issues that you may encounter. Here are some tips on how to identify and fix these issues.

Identifying and Fixing Misfires

One of the most common issues related to spark plugs is engine misfires. Misfires can be caused by a variety of factors, including a loose spark plug or a damaged cylinder head. If you are experiencing misfires, the first step is to check the spark plugs to make sure they are tightened to the correct torque. Refer to your vehicle’s manual or an online database to find the appropriate torque specifications.

If the spark plugs are tightened to the correct torque and you are still experiencing misfires, you may need to replace the spark plugs. Make sure to use the correct type of spark plug for your vehicle and tighten them to the correct torque.

Dealing with Damaged Threads and Components

Another common issue related to spark plugs is damaged threads or components. If you notice that the spark plug threads are damaged, you may need to replace the cylinder head. This is a more complex repair that should be performed by a professional mechanic.

If the spark plug itself is damaged, you can replace it yourself. Make sure to use the correct type of spark plug for your vehicle and tighten it to the correct torque. If you are unsure how to replace a spark plug, refer to your vehicle’s manual or an online database for instructions.

In conclusion, troubleshooting common issues related to spark plug torque can be a simple process that can save you time and money in the long run. By identifying and fixing issues such as misfires and damaged threads, you can ensure that your vehicle is running smoothly and efficiently.

As an Amazon Associate we earn from qualifying purchases.