Flex pipes are an essential component of your vehicle’s exhaust system. They are designed to absorb vibrations and movements in the exhaust system while also allowing for flexibility in the exhaust system’s joints. In this article, we will cover the basics of flex pipes, including their function, symptoms of failure, and replacement tips.

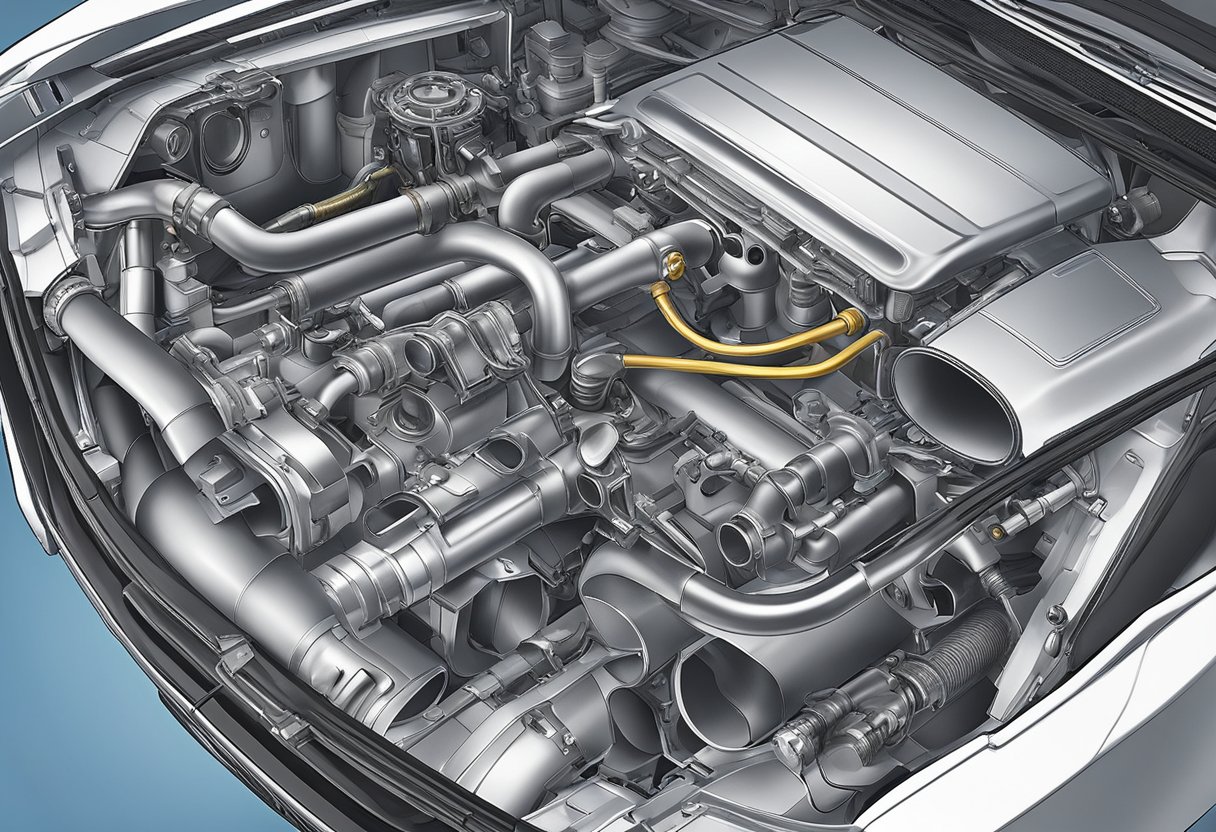

The function of a flex pipe is to allow for movement in the exhaust system while also reducing stress on the system’s joints. Flex pipes are typically made of stainless steel and feature a bellows design that allows for expansion and contraction. They are located in the exhaust system between the engine and the catalytic converter or muffler.

Symptoms of a failing flex pipe can include loud rattling or banging noises, decreased engine performance, and decreased fuel efficiency. If left unaddressed, a damaged flex pipe can lead to more significant issues with your vehicle’s exhaust system, including damage to the catalytic converter or muffler. In the next section, we will discuss the signs of a failing flex pipe in more detail.

Understanding Flex Pipes

Definition and Purpose

Flex pipes, also known as flex couplings or flex bellows, are components of an exhaust system that are designed to absorb vibrations and movements caused by the engine and the vehicle’s suspension. They are typically made of a flexible metal bellows with two flanges that are connected to the exhaust pipes.

The main purpose of a flex pipe is to prevent stress on the exhaust system caused by the engine’s movements. Without a flex pipe, the exhaust system would be prone to cracking or breaking due to the constant movement of the engine.

Types of Flex Pipes

There are two main types of flex pipes: braided and bellows. Braided flex pipes are made of interlocking metal braids that are wrapped around a thin-walled metal tube. Bellows flex pipes, on the other hand, are made of a series of metal plates that are welded together to form a flexible accordion-like structure.

Braided flex pipes are more commonly used in aftermarket exhaust systems because they are cheaper to manufacture and easier to install. Bellows flex pipes, on the other hand, are typically used in OEM exhaust systems because they are more durable and can withstand higher temperatures and pressures.

Materials Used

Flex pipes are typically made of stainless steel or aluminized steel. Stainless steel is more expensive but is more durable and resistant to corrosion. Aluminized steel is cheaper but is less durable and more prone to rusting.

Some aftermarket flex pipes are also made of flexible materials such as silicone or rubber. These materials are less durable than metal but are more flexible and can absorb more vibrations. However, they are not as heat-resistant as metal and are not recommended for high-performance or high-temperature applications.

Overall, understanding the different types of flex pipes and the materials they are made of can help you choose the best one for your vehicle and ensure that your exhaust system functions properly.

Common Symptoms of Flex Pipe Failure

If you suspect that your vehicle’s flex pipe is failing, there are a few key symptoms to look out for. Here are some of the most common signs that your flex pipe may be failing:

Visible Damage

One of the most obvious signs of a failing flex pipe is visible damage. If you notice that the flex pipe is cracked or has holes in it, it’s likely that it’s no longer functioning properly. In some cases, the flex pipe may even be hanging off the exhaust system, which can cause additional damage and create a safety hazard.

Unusual Noises

Another common symptom of flex pipe failure is the presence of unusual noises. If you hear a rattling or clunking sound coming from your exhaust system, it could be a sign that the flex pipe is damaged. This is because a damaged flex pipe can cause the exhaust system to vibrate, which can create these types of noises.

Exhaust Leaks

A failing flex pipe can also cause exhaust leaks. This is because the flex pipe is responsible for absorbing the vibrations that are created by the engine and exhaust system. When the flex pipe is damaged, it can no longer do this effectively, which can cause leaks to occur.

Performance Issues

Finally, a failing flex pipe can also cause performance issues. This is because the flex pipe is responsible for regulating the flow of exhaust gases through the exhaust system. When it’s damaged, it can cause a decrease in power and acceleration, as well as reduced fuel efficiency.

If you notice any of these symptoms, it’s important to have your flex pipe inspected and replaced if necessary. By taking care of this issue early on, you can prevent further damage to your exhaust system and ensure that your vehicle is operating safely and efficiently.

Diagnosing Flex Pipe Issues

Flex pipes are an essential component of your vehicle’s exhaust system. They are designed to absorb vibrations and movements that occur in the exhaust system. However, over time, flex pipes can wear out and fail. Here are some symptoms of a failing flex pipe and how to diagnose the issue.

Visual Inspection

One of the easiest ways to diagnose a failing flex pipe is through a visual inspection. You can do this by examining the flex pipe for any signs of damage or wear. Look for cracks, holes, or rust on the flex pipe. If you notice any of these signs, it’s likely that your flex pipe needs to be replaced.

Pressure Testing

Another way to diagnose a failing flex pipe is through pressure testing. This involves using a pressure gauge to measure the pressure inside the exhaust system. If the pressure is too high, it could be a sign that the flex pipe is clogged or damaged.

Professional Diagnosis

If you’re unsure about the state of your flex pipe, it’s always best to seek professional help. An experienced mechanic can diagnose the issue and provide you with the best course of action. They may use specialized tools to check for leaks or other issues that could be affecting the performance of your exhaust system.

In conclusion, diagnosing a failing flex pipe requires a visual inspection, pressure testing, or professional diagnosis. By identifying the symptoms of a failing flex pipe early on, you can avoid costly repairs and keep your vehicle running smoothly.

What are the symptoms of failure for a flex pipe, and how does it compare to symptoms of A/C compressor failure?

The symptoms of failure for a flex pipe include loud exhaust noises, visible cracks, and decreased fuel efficiency. In comparison, a/c compressor failure symptoms can include warm air blowing from the vents, strange noises, and leaking refrigerant. Both issues require immediate attention to prevent further damage to the vehicle.

What are the symptoms of flex pipe failure that could trigger the service engine soon light?

The symptoms of flex pipe failure that could trigger the service engine soon light include loud exhaust noises, decreased fuel efficiency, and decreased engine performance. If you encounter this issue, it’s important to address it immediately and consider a service engine soon light reset to clear any codes related to the problem.

Replacing a Flex Pipe

Choosing the Right Replacement

When it comes to replacing a flex pipe, it’s important to choose the right replacement part. You should consider the make and model of your vehicle, as well as the type of exhaust system you have. It’s also important to choose a replacement that is made from high-quality materials to ensure that it will last.

Tools and Equipment Needed

Before you begin the replacement process, you will need to gather a few tools and equipment. These may include:

- Jack stands

- Socket wrench set

- New flex pipe

- Exhaust clamps

- Penetrating oil

- Safety glasses

Step-by-Step Replacement Process

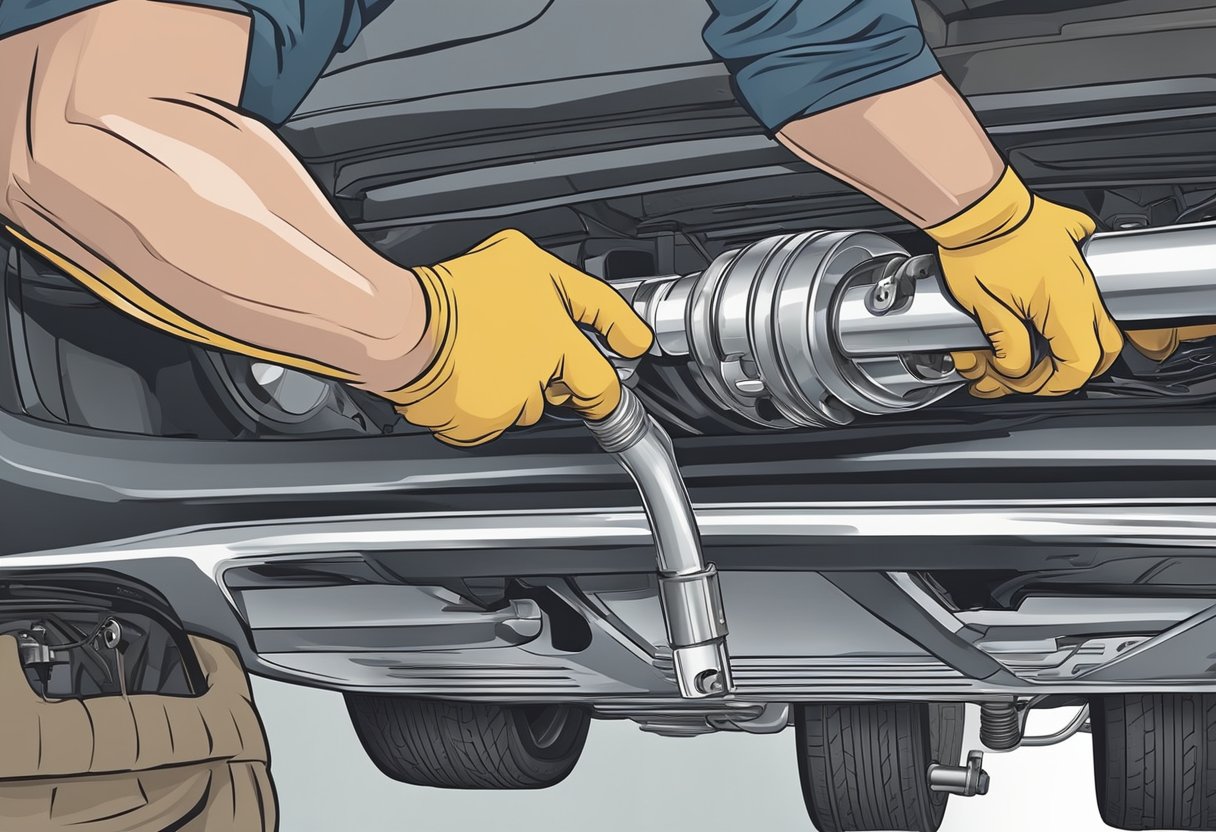

Replacing a flex pipe can be a challenging task, but with the right tools and knowledge, it can be done. Here’s a step-by-step guide to help you through the process:

- First, raise your vehicle up on jack stands and locate the damaged flex pipe.

- Use a socket wrench set to remove the bolts that hold the flex pipe in place.

- Apply penetrating oil to the bolts if they are rusted or difficult to remove.

- Remove the damaged flex pipe and set it aside.

- Install the new flex pipe in its place, making sure it is properly aligned.

- Use exhaust clamps to secure the new flex pipe in place.

- Tighten the bolts with a socket wrench set, making sure they are snug but not too tight.

- Start your vehicle and check for any leaks or unusual sounds.

By following these steps, you can replace a damaged flex pipe and get your vehicle back on the road in no time.

Maintenance Tips to Prevent Flex Pipe Failure

Flex pipes are an essential part of your vehicle’s exhaust system, and they can be prone to failure if not maintained properly. To prevent costly repairs and replacements, it’s important to take care of your flex pipes. Here are some maintenance tips to help prevent flex pipe failure:

Regular Inspections

Regular inspections are crucial to identifying any issues with your flex pipes before they become major problems. Inspect your exhaust system for any signs of damage, such as cracks, rust, or holes. Also, pay attention to any unusual noises or vibrations coming from your exhaust system, as these can be symptoms of a failing flex pipe.

Proper Installation

Proper installation is key to ensuring your flex pipes last as long as possible. Make sure your flex pipes are installed correctly and securely, with no leaks or loose connections. A faulty installation can cause stress on the flex pipe, leading to premature failure.

Avoiding Stress on the Exhaust System

Avoiding stress on your exhaust system can help prevent flex pipe failure. This means avoiding rough or uneven terrain, as well as heavy loads and aggressive driving. Additionally, using the correct octane fuel for your vehicle can help reduce stress on your exhaust system.

By following these maintenance tips, you can help prevent flex pipe failure and keep your vehicle running smoothly. Regular inspections, proper installation, and avoiding stress on your exhaust system are all important steps in maintaining your vehicle’s exhaust system.

As an Amazon Associate we earn from qualifying purchases.