If you are experiencing the P0325 error code on your vehicle, it means that there is an issue with the knock sensor circuit.

The knock sensor is responsible for detecting engine knock or detonation, which can cause damage to the engine if left unchecked.

This error code can be frustrating to deal with, but there are solutions available to help you diagnose and fix the problem.

One of the first steps in diagnosing the P0325 error code is to check the wiring and connections for the knock sensor circuit.

A damaged or corroded connection can cause the sensor to malfunction, so it is important to ensure that the wiring is in good condition.

Another potential cause of the error code is a faulty knock sensor, which may need to be replaced if it is not functioning properly.

Fortunately, there are several solutions available to help you fix the P0325 error code and get your vehicle back on the road.

By following the proper diagnostic procedures and taking the necessary steps to repair or replace any damaged components, you can ensure that your engine is running smoothly and avoid any potential damage or costly repairs down the line.

Understanding the P0325 Code

When your vehicle’s check engine light comes on and you scan the codes, seeing P0325 can be concerning.

This code indicates that there is a malfunction in the knock sensor circuit, which can cause engine performance issues and potentially lead to engine damage if left unresolved.

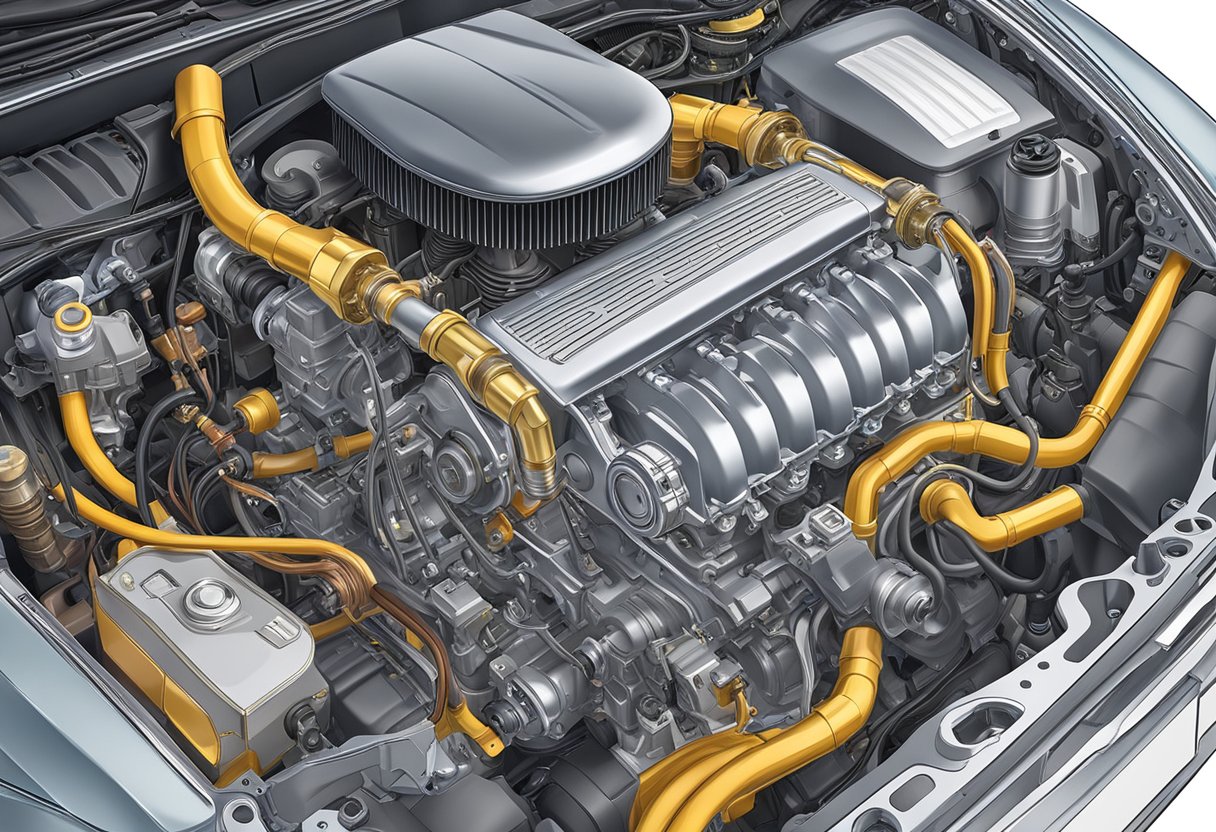

The knock sensor is responsible for detecting engine knocking or pinging, which can occur when the air/fuel mixture in the combustion chamber ignites prematurely.

This can cause damage to the engine and reduce performance.

The knock sensor sends a signal to the engine control module (ECM), which then adjusts the ignition timing to prevent knocking.

When the ECM detects a malfunction in the knock sensor circuit, it sets the P0325 code.

This can be caused by a variety of issues, including a faulty knock sensor, damaged wiring or connectors, or a malfunctioning ECM.

To diagnose the issue, a mechanic will typically use a scan tool to read the code and then perform a visual inspection of the wiring and connectors.

They may also test the knock sensor using a multimeter or oscilloscope.

Once the issue has been identified, the mechanic can then determine the appropriate solution.

This may involve replacing the knock sensor, repairing damaged wiring or connectors, or replacing the ECM.

Overall, it is important to address a P0325 code promptly to prevent potential engine damage and ensure optimal performance.

Tools and Equipment Needed

To diagnose and fix a P0325 knock sensor malfunction, you will need a few tools and equipment. Here are the essentials:

Diagnostic Scan Tool

A diagnostic scan tool is necessary to retrieve the diagnostic trouble codes (DTCs) from the vehicle’s onboard computer.

You can use a handheld diagnostic scan tool or a laptop with diagnostic software.

The scan tool should be able to read manufacturer-specific codes, freeze frame data, and real-time data.

Multimeter

A multimeter is a versatile tool that measures voltage, resistance, and current.

You can use a multimeter to test the knock sensor’s resistance and continuity, as well as other electrical components in the engine.

Knock Sensor Socket

A knock sensor socket is a specialized tool that fits over the knock sensor and allows you to remove and install it without damaging the sensor or the engine.

The socket should be the correct size for your vehicle’s knock sensor.

Torque Wrench

A torque wrench is essential for tightening the knock sensor to the manufacturer’s specifications.

Over-tightening or under-tightening the sensor can cause it to malfunction or damage the engine.

Electrical Contact Cleaner

Electrical contact cleaner is a spray that removes dirt, grime, and corrosion from electrical connections.

You can use it to clean the knock sensor’s electrical connector and other electrical components in the engine.

Safety Equipment

Safety equipment, such as gloves and safety glasses, is essential when working on the engine.

Gloves protect your hands from cuts, burns, and chemicals, while safety glasses protect your eyes from debris and fluids.

Step-by-Step Diagnostic Process

If you have encountered P0325 code, it is important to diagnose the issue immediately to avoid further damage to your vehicle.

Here are the steps you should follow to diagnose and fix the knock sensor malfunction:

Verify the Code

The first step is to verify the code. You can do this by using an OBD-II scanner to read the code.

If the scanner displays P0325 code, then you can proceed with the diagnostic process.

Inspect the Knock Sensor

The next step is to inspect the knock sensor. Check for any physical damage or wear and tear on the sensor.

Ensure that the sensor is properly installed and tightened. If you notice any damage, replace the sensor.

Test the Knock Sensor

Once you have inspected the knock sensor, it is time to test it.

You can do this by using a digital multimeter to check the resistance of the sensor.

A functioning knock sensor should have a resistance of around 5-7 ohms.

If the resistance is outside of this range, then the sensor is faulty and needs to be replaced.

Check the Wiring and Connectors

If the knock sensor is functioning properly, then the issue could be with the wiring or connectors.

Check for any loose or damaged wires and connectors. Ensure that the wires are properly connected and not corroded.

If you notice any issues, repair or replace the wiring and connectors.

By following these steps, you can diagnose and fix the knock sensor malfunction.

It is important to address this issue promptly to ensure the longevity of your vehicle.

Common Causes of P0325

If you are experiencing a P0325 code, it is likely that there is an issue with your vehicle’s knock sensor.

However, there are a few common causes that can trigger this code. Here are some of the most common causes of P0325:

-

Faulty knock sensor: The knock sensor is responsible for detecting vibrations in the engine caused by detonation or pre-ignition.

If the knock sensor is faulty, it may not be able to detect these vibrations, which can trigger a P0325 code.

-

Wiring issues: The knock sensor is connected to the engine control module (ECM) via a wiring harness.

If there is a problem with the wiring, such as a short or open circuit, the ECM may not be able to receive a signal from the knock sensor, which can trigger a P0325 code.

-

Failed ECM: In rare cases, a failed ECM can cause a P0325 code.

If the ECM is not able to receive a signal from the knock sensor, it may assume that there is a problem with the sensor and trigger the code.

-

Engine mechanical problems: Issues with the engine, such as worn bearings or a damaged crankshaft, can cause vibrations that can trigger a P0325 code.

It is important to address any mechanical issues with the engine to prevent further damage.

-

Poor quality fuel: Using poor quality fuel can cause detonation or pre-ignition, which can trigger the knock sensor and cause a P0325 code.

It is important to use high-quality fuel to prevent these issues.

By understanding the common causes of P0325, you can better diagnose and fix the issue with your vehicle’s knock sensor.

If you are unsure about the cause of the code, it is always best to consult with a qualified mechanic.

Repair and Replacement Procedures

Repairing Wiring Issues

If the diagnostic process has indicated that the knock sensor malfunction is due to a wiring issue, the first step is to visually inspect the wiring harness and connectors for any visible signs of damage or corrosion.

If any damage is found, the affected wiring should be repaired or replaced as necessary.

If no visible damage is found, the next step is to use a multimeter to check the resistance of the wiring.

The resistance should be within the manufacturer’s specified range.

If the resistance is outside of the specified range, the affected wiring should be repaired or replaced.

Replacing the Knock Sensor

If the diagnostic process has indicated that the knock sensor needs to be replaced, the following steps should be taken:

-

Disconnect the negative battery cable to prevent any electrical shock or damage to the vehicle’s electrical system.

-

Locate the knock sensor. It is typically located near the engine block or cylinder head.

-

Disconnect the electrical connector from the knock sensor.

-

Use a socket or wrench to remove the knock sensor from its mounting location.

-

Install the new knock sensor in its mounting location and tighten it to the manufacturer’s specified torque.

-

Reconnect the electrical connector to the knock sensor.

-

Reconnect the negative battery cable.

It is important to note that if the knock sensor is mounted in a difficult-to-reach location, it may be necessary to remove other components or parts of the vehicle to gain access to the sensor.

In this case, it is recommended to consult the vehicle’s service manual for specific instructions.

Preventative Measures and Maintenance Tips

To avoid encountering a P0325 code due to a knock sensor malfunction, there are several preventative measures and maintenance tips you can follow.

These include:

-

Regularly inspecting and cleaning the engine: Dirt, debris, and oil buildup can cause knock sensor issues.

Regularly cleaning the engine and replacing dirty air filters can help prevent these issues from occurring.

-

Using high-quality fuel: Low-quality fuel or fuel with high levels of ethanol can cause engine knock, which can trigger a knock sensor malfunction.

Using high-quality fuel can help prevent this issue.

-

Checking the electrical connections: Loose or corroded electrical connections can cause knock sensor issues.

Regularly checking and tightening these connections can help prevent problems.

-

Replacing worn-out parts: Worn-out spark plugs, ignition coils, and other engine components can cause engine knock, which can trigger a knock sensor malfunction.

Regularly replacing these parts can help prevent issues.

By following these preventative measures and maintenance tips, you can help prevent a knock sensor malfunction and avoid encountering a P0325 code.

As an Amazon Associate we earn from qualifying purchases.